커뮤니티

부경투데이

- 국립 부경대학교의 다양한 모습과 소식을 접하시면 부경대학교가 한번 더 가까워집니다.

| ‘잘려도 다시 붙는’ 신소재 개발 ‘주목’ (Development of self-healing 'new material' that repairs damages) | |||

| 작성자 | 대외협력과 | 작성일 | 2021-05-11 |

| 조회수 | 1018 | ||

| ‘잘려도 다시 붙는’ 신소재 개발 ‘주목’ (Development of self-healing 'new material' that repairs damages) | |||||

|

대외협력과 |  |

2021-05-11 |  |

1018 |

부경대-화학연 연구팀, 세계 최고 강도 자가치유 신소재 개발

- 고분자공학과 엄영호 교수 연구팀 성과

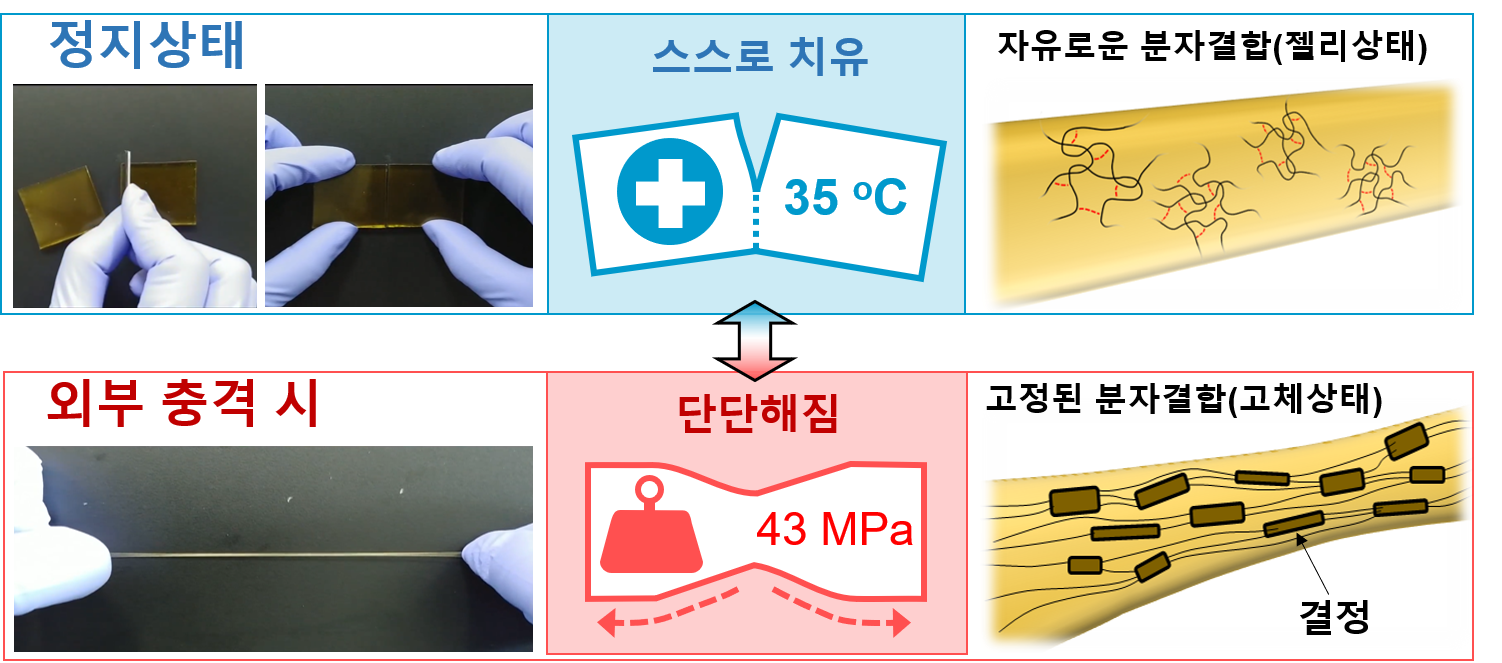

△ 신소재의 정지 시, 외부 충격 시 특성을 나타낸 그림.

부경대학교 등 국내 연구진이 세계 최고 강도의 자가치유(self-healing) 신소재를 개발해 전국 언론의 주목을 받고 있다.

연합뉴스를 비롯, YTN, 동아사이언스 등 전국 언론들은 부경대와 한국화학연구원 공동 연구팀이 세계 최고 수준의 기계적 강도를 갖는 자가 치유 신소재를 개발했다는 소식을 5월 10일 일제히 보도했다. 부경대 고분자공학과 엄영호 교수(왼쪽 사진) 연구팀과 화학연 오동엽, 박제영, 황성연 박사는 공동연구를 진행, 실온에서 절단돼도 스스로 회복하는 자가치유 기능을 가지면서 신발 밑창만큼 질긴 소재를 개발해냈다.

부경대 고분자공학과 엄영호 교수(왼쪽 사진) 연구팀과 화학연 오동엽, 박제영, 황성연 박사는 공동연구를 진행, 실온에서 절단돼도 스스로 회복하는 자가치유 기능을 가지면서 신발 밑창만큼 질긴 소재를 개발해냈다.

자가치유 소재는 외부 환경에 의해 손상을 입은 고분자가 스스로 결함을 감지해 자신의 구조를 복구하고 원래의 기능을 회복할 수 있는 지능형 재료를 말하는데, 이번에 개발된 소재는 지금까지 개발된 자가치유 소재 가운데 기계적 강도가 가장 높은 것으로 나타났다.

연구팀은 기존 상업화 소재인 열가소성 폴리우레탄 기본 골격에 특수한 카보네이트(Carbonate) 화합물을 이용해 개발에 성공했다. 외부 충격을 받으면 순식간에 물질의 분자 결합이 견고해지면서 단단한 결정으로 변해 충격으로부터 스스로 보호하고, 충격 후에는 분자 이동이 자유로운 부드러운 상태로 돌아가 손상을 스스로 회복하는 원리다.

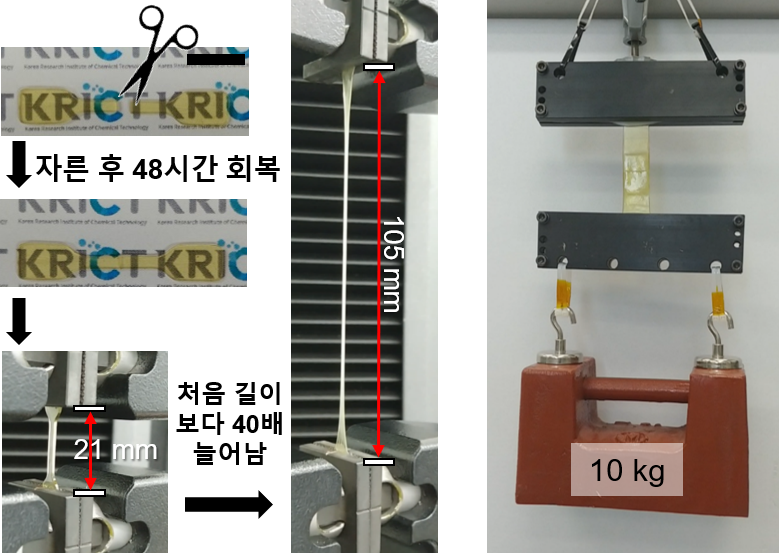

기존 개발된 자가치유 신소재는 분자가 자유롭게 이동하기 위해 말랑말랑한 소재를 사용해 인장강도가 약하다는 한계가 있었다. 이번에 개발된 소재는 인장강도가 43MPa 이상으로, 외부 압력의 세기에 따라 고체와 젤리 상태를 오가며 단단해지는 정도가 달라지며 충격의 흡수를 조절하고, 손상도 스스로 회복하는 것으로 나타났다. 연구팀이 지난 2018년 개발한 소재보다 6배, 일본 동경대나 이화학학연구소 개발 소재의 20~30MPa 보다 뛰어나다.

엄영호 교수 연구팀이 이 소재의 물리적 특성을 분석한 결과 점도가 높지 않아 다양한 모양으로 성형하는데 유리한 것으로 나타났다.

오동엽 박사는 “개발된 소재를 적용할하면 롤러블·폴더블 디스플레이를 접었다 폈다 하면서 발생하는 손상을 끊임없이 회복해 소재 피로 손상 문제를 극복할 수 있을 것으로 기대된다.”라고 말했다.

이번 연구결과는 국제학술지 <네이처 커뮤니케이션즈> 1월호에 게재됐다. <부경투데이>

△ 신소재를 회복 특성 및 인장강도를 보여주는 그림.

PKNU-KRICT joint research team developed the world's strongest self-healing new material

- The result of Prof. Eom Young-Ho's research team from the Dept. of Polymer Engineering

Researchers in Korea, including Pukyong National University, have developed the world's strongest self-healing new material and are attracting national media attention.

Yonhap News, YTN, Dong-A Science, and other national media reported on May 10th that the joint research team of Pukyong National University and the Korea Research Institute of Chemical Technology (KRICT) developed a new self-healing material with the world's strongest mechanical strength.

Professor Eom Young-Ho of the Department of Polymer Engineering at Pukyong National University (photo, left) and his research team conducted joint research with Oh Dong-Yeop, Park Je-Young, and Hwang Seong-Yeon, who are from a research team from the Korea Research Institute of Chemical Technology. Together they developed a material that is as tough as a shoe outsole while having self-healing capabilities that recovers itself even if it is cut at room temperature.

Self-healing material refers to an intelligent material that allows polymers damaged by the external environment to detect defects independently, restore their structure, and return to their original functions. The material developed this time was found to have the highest mechanical strength among the self-healing materials developed so far.

The research team succeeded in developing it using a special carbonate compound in the basic build of thermoplastic polyurethane, an existing commercial material. When an external force impacts it, the material's molecular bonds become solid in an instant and turn into a hard crystal so that it protects itself from impact. After impact, it returns to a soft state in which molecules are free to move and recovers the damage by itself.

Existing self-healing materials have a limitation in that the tensile strength is weak because they use a soft material to move molecules freely. The newly developed material is found to have a tensile strength of 43 MPa or more, hardens between solid and jelly states depending on the strength of external pressure, controls the absorption of shock, and recovers damage by itself. It is 6 times better than the material developed by the research team in 2018 and 20~30MPa stronger than the material developed by the University of Tokyo or the Institute of Physical and Chemical Research (RIKEN) in Japan.

As a result of analyzing the physical properties of this material, Prof. Eom Young-Ho's research team found that it was advantageous in molding into various shapes due to its low viscosity.

Dr. Oh Dong-Yeop said, "If we apply the newly developed material, it is expected that we will be able to overcome the problem of material fatigue by constantly recovering from damage caused by folding and unfolding rollable and foldable displays."

The research results were published in the January issue of Nature Communications, an international academic journal. <Pukyong Today>